FS621M

Metal 3D Printing Platform

Industrial Scale Metal Laser Sintering System

with 1.7 Meter Z Height

Addressing the metal manufacturing challenges including productivity, size constraints, powder management, process control and factory layout, our team developed the all-new FS621M by co-innovating with our key industry partner in the aerospace industry, with focuses on extended build cylinder volume and maximum productivity per laser.

Features

EXTRA-LARGE BUILD VOLUME

With a build plate size of 620 × 620 mm and a vertical axis measuring 1.1 meters, the FS621M boasts one of the most capacious metal laser sintering build volumes available in the market. Its expansive build envelope unlocks novel opportunities for large-scale metal production, enabling achievements that were previously unattainable in sectors like aerospace, oil and gas, and others.

HIGH PRODUCTIVITY

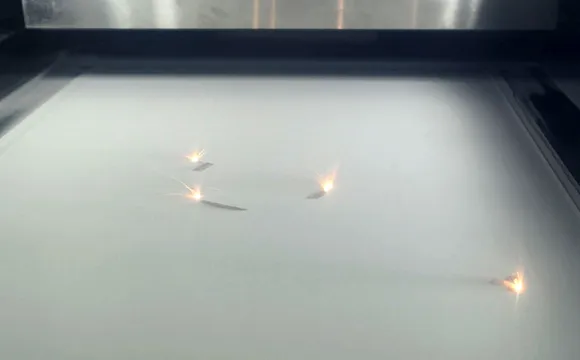

Equipped with a single 1000 W laser or four 500 W lasers, the FS621M delivers unparalleled productivity. The open platform allows users to customize build parameters for cost-competitive metal additive manufacturing. An advanced dynamic 3-axis scanning system, robust build process control, and real-time recoating monitoring work in tandem to guarantee its top-notch build quality.

OPTIMIZED OPERATION

The filter module is designed with a secondary circulating system and a dual-station filter setup. This enables seamless filter replacement without disrupting the ongoing build process. The powder handling system features a unified powder container design for loading, unloading, and sieving, which offers a fully-sealed powder handling environment, facilitating smooth transportation between different stations and guaranteeing the safe storage of materials.

Technical Data

| External Dimensions (L × W × H): | 5890 × 4350 × 3940 mm |

| Build Cylinder Size (L × W × H): | 620 × 620 × 1100 mm (Incl. build plate) |

| Net Weight: | Approx. 8000 kg |

| Layer Thickness: | 0.02 ~ 0.1 mm |

| Maximum Scan Speed: | 10 m/s |

| Laser Type: | Fiber laser, Single Laser, 1 × 1000 W or Quad Lasers, 4 × 500 W |

| Scanner: | F theta lenses |

| Inert Gas Protection: | Argon/ Nitrogen |

| Average Inert Gas Consumption in Process: | 8-10 L/min |

| Operating System: | 64 bit Windows 10 |

| Comprehensive Software: | BuildStar, MakeStar |

| Key Software Features: | Open machine key parameters, real-time build parameter modification, three-dimensional visualization, diagnostic functions |

| Data File Format: | STL |

| Power Supply: | 400 V ± 10%, 3~/ N/ PE, 50 Hz, 60 A |

| Operating Ambient Temperature: | 22-28℃ |

| Materials: | IN625, IN718, TA15, 304L, 316L, Ti6Al4V, AlSi10Mg, CuCrZr, etc. |

Aerospace Combustion Chamber

Machine: FS621M

Material: IN718

Size: 550 x 550 x 780 (H) mm

The additive manufactured Inconel combustion chamber measures 780mm (30.7 inches) in height and 550mm (21.7 inches) in diameter. Major challenges include the size of the build, function integration, and detail resolution. The advanced additive manufacturing enabled many new innovations from engineers including consolidated design, light-weight lattice structures, and complex geometries.