UT252P

Plastic 3D Printing Platform

A Powerful + Ultra Temperature industrial 3D printer

for your additive manufacturing needs

The UT252P offers a compact build envelope size, robust high-temperature capabilities combined with truly open parameter strategy making it the best flexible machine solution for SLS material development and small batch economy production.

Features

HIGH TEMPERATURE

The 252P Series offers three configurations capable of achieving chamber temperature requirements: 220℃(HT), 280℃(ST) and 340℃(UT). Enhanced temperature shielding, laser power and thermal controls enable the 252P Series to process high-performance materials such as PA6, PPS, PAEK, PI, PTFE for direct-use applications.

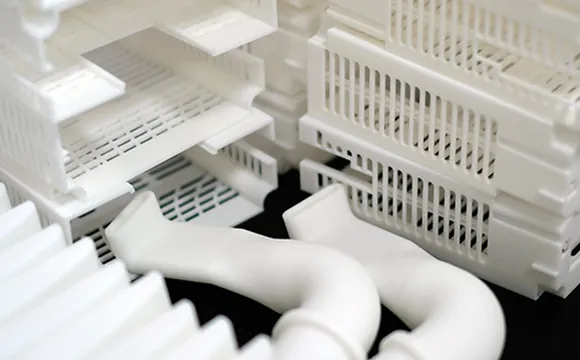

VERSATILE APPLICATIONS

With the 252P series, we are able to support a wide range of additive solutions in various industries including scientific research, automotive, medical, and aerospace. Like all other Farsoon systems the 252P series is open platform allowing for unprecedented freedom in manufacturing and material development.

COMPREHENSIVE SOFTWARE

The 252P series is offered with a full set of self-developed software. This powerful set of tools enables a variety of functions that range from build preparation to machine control and operations while remaining completely compatible with third party software and materials.

Technical Data

| External Dimensions (L×W×H): | 1735×1300×2000 mm |

| Build Cylinder Size (L×W×H): | 250×250×320 mm |

| Net Weight: Approx. | 2500 kg |

| Layer Thickness: | 0.06~0.3 mm |

| Maximum Scan Speed: | 10 m/s |

| Laser Type: | CO2 laser, 1×100W |

| Scanner: | High-precision galvo system |

| Inert Gas Protection: | Nitrogen |

| Maximum Chamber Temperature: | 340℃ |

| Temperature Regulation: | Continuous real-time surface temperature monitoring |

| Operating System: | 64 bit Windows 10 |

| Comprehensive Software: | BuildStar, MakeStar |

| Key Software Features: | Open machine key parameters, real-time build parameter modification, three-dimensional visualization, diagnostic functions |

| Data File Format: | STL |

| Power Supply: | 400 V±10%, 3~/N/PE, 50/60 Hz, 32 A |

| Operating Ambient Temperature: | 22-28℃ |

| Materials: | PA, PP, PPS, TPU, PAEK, etc. |

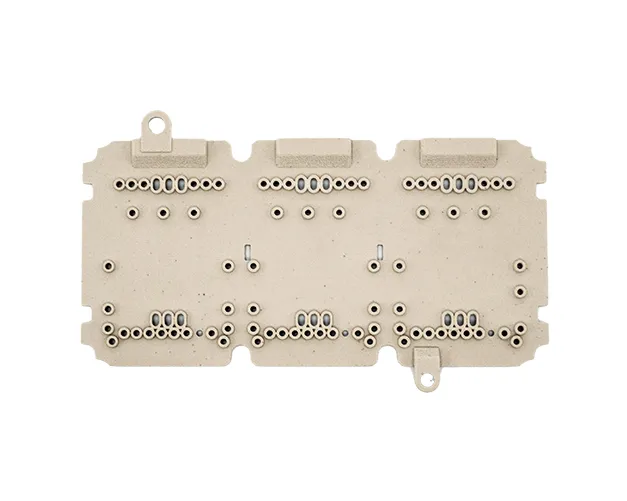

HPD Package Module Cover

Machine: UT252P

Material: PAEK family

The main function of the HPD module is to control speed and torque, enabling vehicle acceleration, deceleration, and automation. The 3D-printed PAEK cover plate maintains excellent and stable performance even under high-temperature, high-frequency testing. It can withstand temperatures up to 175ºC and remains stable for up to 1.5 hours at 200ºC without deformation. In terms of mechanical properties, it meets strength requirements of over 30 MPa and modulus above 1500 MPa.