BM120×100

Metal 3D Printing Post Processing

Precise EDM Wire Cut Machine

for Additive Manufacturing Post Processing

Our electro-erosion wire cut machines are designed for cutoff of the metal additive manufacturing parts with various shapes and sizes. These machines allow you to process parts, made of different brands of steel, high-strength composite alloys, titanium, graphite and more.

Features

HIGH PRECISION & ACCURACY

EDM Wire Cut can achieve extremely tight tolerance. The process minimizes heat distortion, allowing for precise cuts with smooth surface finishes, sometimes eliminating the need for further polishing.

MATERIAL FLEXIBILITY

EDM Wire Cut machine can machine a wide range of electrically conductive materials. It can work with various metals, including brass, copper, molybdenum, aluminium, and tungsten, as well as some ceramics and composites. Also suits heat-sensitive materials.

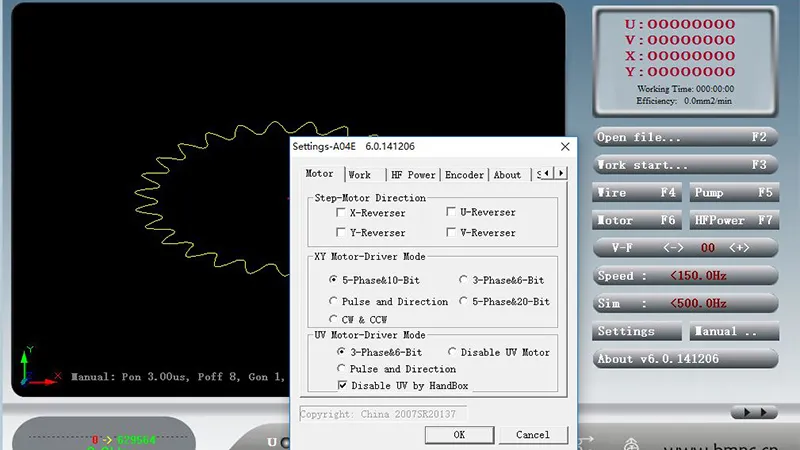

OPERATION EASE

User-friendly operate interface. Complicated and very minute shapes can be efficiently machined by unskilled operators using programs alone. On top of that, the machining time required can be accurately predicted to facilitate process and delivery control.

Technical Data

Specifications:

| XY Axis Travel: | 1200 × 1000 mm |

| Worktable Size: | 1600 × 1090 mm |

| Cutting Thickness: | Four options, Max. 500 mm (D type), Max. 800 mm (R type), Max. 1000 mm (I type), Max. 1500 mm (L type) |

| Taper Cutting: | ± 3° (Thickness ≤ 100 mm) |

| Loading Weight: | Max. 5000 kg |

| Machine Weight: | 7000 kg-7500 kg (L type) |

Processing Parameters:

| Cutting Precision: | 0.015 mm |

| Machining Efficiency: | 150 mm2/min |

| Work Current: | Max. 6 A |

| Work Power: | 3-phase 380 V±5%, 50 Hz |

Configurations:

| XY Axis Control: | Servo control |

| Z Axis Elevation Control: | Automated |

| Screw and Guide Rail: | Precision ball screw/ Precision linear guide rail |

| Wire Type: | Molybdenum wire |

| Wire Feeding System: | Converter control |

| Hand Cranked Pulse: | Standard |

| Working Liquid: | Water-based liquid |

| Working Liquid Filter System: | Multiple filtration |

| Cabinet: | BMW3000 |

| Machine body: | Separate-type machine body, Meehanite cast iron (HT250) |