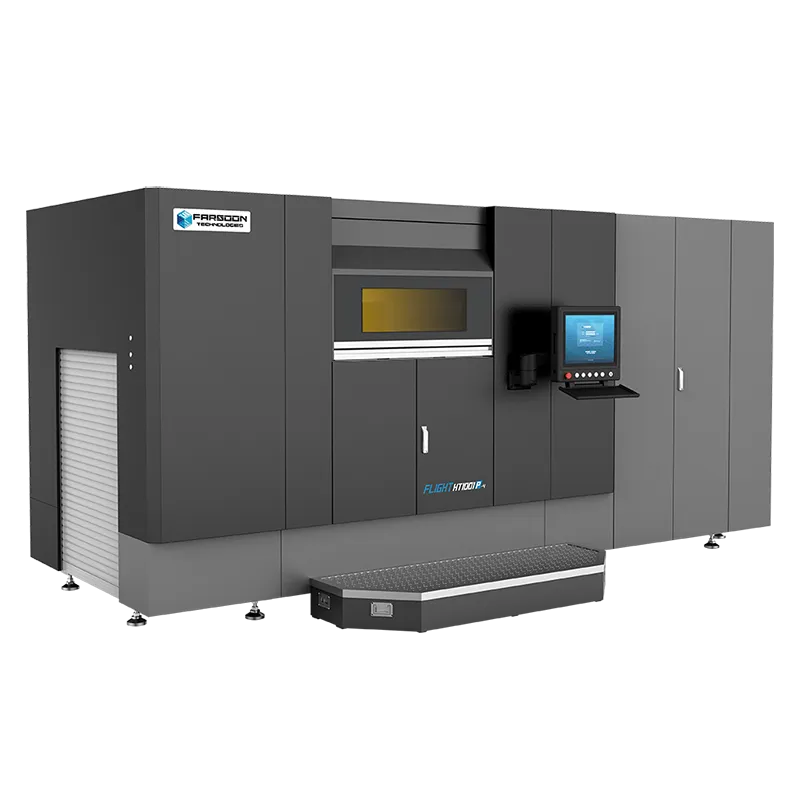

FLIGHT HT1001P

Plastic 3D Printing Platform

Ultimate System for Productivity

The innovative application of high-speed FLIGHT® Technology on HT1001P CAMS platform boosts industry-leading productivity for large-sized parts. Featuring expanded build cylinder measuring 1000 × 500 × 450mm and powerful quad 300-watt fiber lasers, the Flight® HT1001P creates four ultra-fine laser spots with fast scanning speed of up to 20 m/s (66ft/s) for each; the continuous batch production capability significantly improves machine uptime and offers up to 10 times throughput yield per floor area compared to standard SLS system within the same time frame.

Features

OPEN & MODULAR

The FLIGHT® HT1001P systems is fully open. Besides a list of standard material config files ready for serial production, the users have full access to a wide range of key parameters for tuning customized processing parameters from third party engineering materials. In addition, the FLIGHT® HT1001P’s modular design allows for the easy addition of future stations for pre and post processing as well as integration into existing production lines.

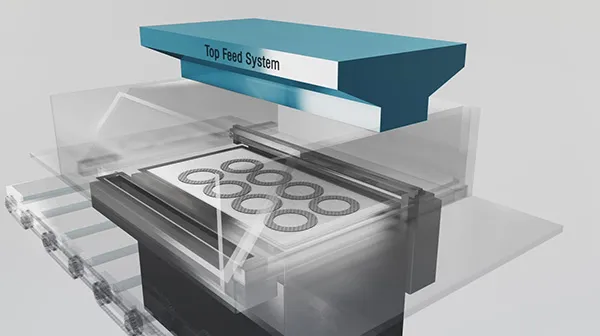

POWDER MANAGEMENT

Designed for industrial-scale manufacturing, the FLIGHT® HT1001P system is featured with a comprehensive, closed-loop powder handling system with increased level automation and minimal operator interaction with the powder. Highly efficient top-feeding powder delivery, robust roller re-coating system and fully enclosed de-powdering station enables streamlined material workflow with improved productivity, safety and operation ease.

QUALITY ENGINEERING PARTS

The FLIGHT® HT1001P is capable of achieving chamber temperatures of up to 220℃ to process high-temperature engineering materials such as PA6 for direct-use end parts. With patented multi-zone heater & intelligent temperature control system, the FLIGHT® HT1001P can achieve a uniform thermal distribution throughout the platform ensuring the consistent mechanical properties and surface quality of the build parts.

Technical Data

| External Dimensions (L×W×H): | 5820 × 2375 × 2185 mm (Full Module) |

| Build Cylinder Size (L×W×H): | 1000 × 500 × 450 mm |

| Net Weight: | Approx. 5000 kg |

| Layer Thickness: | 0.06~0.3 mm |

| Maximum Scan Speed: | 20 m/s |

| Laser Type: | Fiber Laser, 4×300W |

| Scanner: | High-precision three-axis galvo system |

| Maximum Chamber Temperature: | 220℃ |

| Temperature: | Continuous real-time surface temperature monitoring |

| Operating System: | 64 bit Windows 10 |

| Comprehensive Software: | BuildStar, MakeStar |

| Key Software Features: | Open machine key parameters, real-time build parameter modification, three-dimensional visualization, diagnostic functions |

| Data File Format: | STL |

| Power Supply: | 380 V ± 10%, 3~/N/PE, 50 Hz/ 60 Hz, 50 A |

| Operating Ambient Temperature: | 22-28℃ |

Truck Air Inlet System Component

Machine: FLIGHT® HT1001P-4

Material: FS3401GB-F (PA12 with Glass Bead filled)

Size: 901×155×372mm

Build Time: 10 Hours

The Truck Air Inlet System Component is designed for functional verification and fabricated in a single piece in 10 hours using FLIGHT® HT1001P-4. The produced part showcases high mechanical properties,size-precision at a significant reduced cost compared to traditional manufacturing.