FS191M

Metal 3D Printing Platform

Compact Metal Laser Sintering System

Ideal for Research & Development

As a new compact design to our metal SLM portfolio, the FS191M is equipped with a versatile build volume of 195 x 195 x 220 mm and a powerful 500-watt laser configuration. The FS191M is ideal for small volume metal series prototypes with fast manufacturing turn-overs rates, versatility, and impressive ROI.

Features

COMPACT & VERSATILE SOLUTIONS

The FS191M offer a Φ195 × 220 mm (6.57L) build cylinder size with a powerful 500 W fiber laser, making it ideal for pilot projects and small-batch production. For R&D, an optional Φ80 × 90 mm build platform reduces material costs and increases flexibility. Users can seamlessly switch between platforms for validation and production. With a compact 0.88 m2 footprint, it fits conveniently into office environments for versatile deployment.

COST-EFFECTIVE PERFORMANCE

The FS191M delivers precision and efficiency with key features like a high-precision F-theta lens, integrated filtration, real-time in-chamber monitoring, innovative recoater design and advanced control card. Its open parameter strategy allows full customization, making it a flexible choice for various industries.

ADVANCED TECHNOLOGIES FOR R&D

Designed for research-driven applications, the FS191M offers high precision and success rates with unique add-on modules and capabilities like SRS (Support Reduction System), high-resolution melt pool monitoring, 3D structured light monitoring, laser beam shaping technology, and a high-temperature build plate.

Technical Data

| External Dimensions (L × W × H) | 1100 × 800 × 2000 mm |

| Build Cylinder Size (L × W × H) | Φ195 x 220 mm (Incl. build plate), Optional size: Φ80 × 90 mm |

| Net Weight | Approx. 600 kg |

| Layer Thickness | 0.02 ~ 0.01 mm |

| Maximum Scan Speed | 10 m/s |

| Laser Type | Fiber laser, 1 × 500 W |

| Scanner | F theta lenses |

| Inert Gas Protection | Argon/ Nitrogen |

| Average Inert Gas Consumption in Process | 1-5 L/min |

| Operating System | 64 bit Windows 10 |

| Comprehensive Software | BuildStar, MakeStar |

| Key Software Features | Open machine key parameters, real-time build parameter modification, three-dimensional visualization, diagnostic functions |

| Data File Format | STL |

| Power Supply | 220 V±10%, 1~/ N/ PE, 50 Hz, 25 A |

| Operating Ambient Temperature | 22-28℃ |

| Materials | 316L, Ti6Al4V, AlSi10Mg, Maraging Steel Grade 300, etc. |

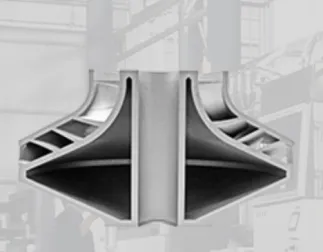

Machine: FS191M

Material: Nickel-based Superalloy

Industry: Aerospace

In the metal laser sintering forming process of closed impellers, it is difficult to remove the internal supports, and the residual supports seriously affect the quality of the build parts. Our solution has reduced the support amount by 99.8%. Only a small amount of support is designed at the impeller shroud.