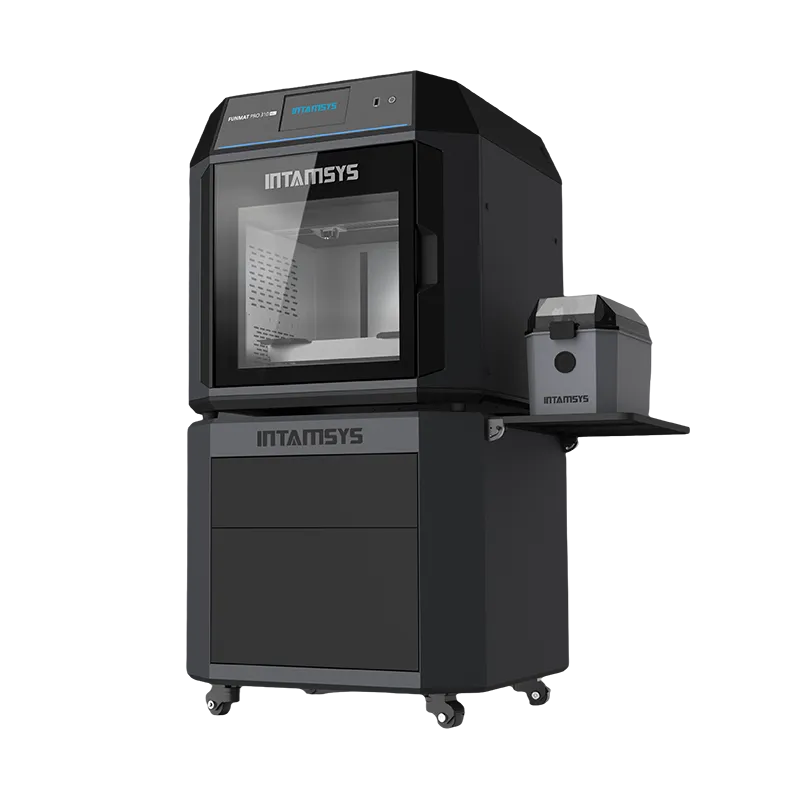

FUNMAT PRO 310 NEO

Filament 3D Printing Platform

Bring Industrial Performance to Your Desktop

The FUNMAT PRO 310 NEO responds to the growing demands of professional engineers with a thermostatic chamber and full-size printing capability on a desktop machine. The thermostatic chamber can reach up to 100 °C to print engineering plastics with a build volume of 305 × 260 × 260 mm. Plug & play and easy-to-remove modular IDEX design provides multiple printing modes. With whole-process control, the printer offers engineering material capabilities such as ASA, ABS, PC, PC-ABS, PA and PA-CF with user-friendly 3D model-slicing software.

Features

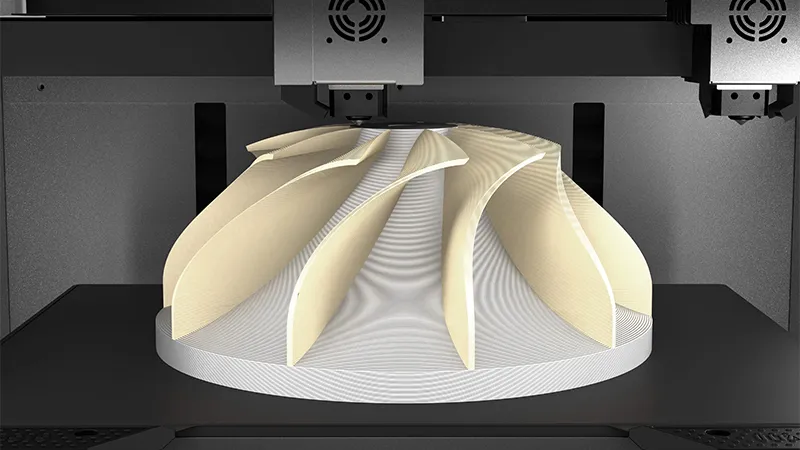

INDUSTRIAL PERFORMANCE

Offers 12+ high-speed material processing options, achieving a productivity range of 500-1000 g/day. Maintains perfect control over print quality and precision at high speed, delivering reliable continuous production to meet industrial application needs.

IDEX

The Mirror/Duplicate Mode, Support Mode, and Dual-Color Mode bring greater design flexibility to your engineers. More inspiration, yet uncompromised print quality.

EASY-TO-USE

Intelligent interactive design with a user-friendly interface and task queue management function. Plug-and-play modular design makes it easy to disassemble and maintain. Standard with independently sealed and dried hopper, complemented by reusable molecular sieves, eliminating the need for continuous filament drying.

Technical Data

Printing

| Technology: | FFF (Fused Filament Fabrication) |

| Build Volume (L × W × H) : | Single nozzle, 305 × 260 × 260 mm; Dual nozzle, 260 × 260 × 260 mm |

| Layer Thickness: | 0.1-0.3 mm |

| Number of Nozzles: | 2 (IDEX) |

| Nozzle Temperature: Max. | 350℃ |

| Filament Diameter: | 1.75 mm |

| Printing Speed: | Max. 500 mm/s |

| Printing Acceleration: | Max. 10000 mm/s2 |

| Nozzle Diameter: | Default: 0.4 mm (Optional 0.25/0.6/0.8 mm) |

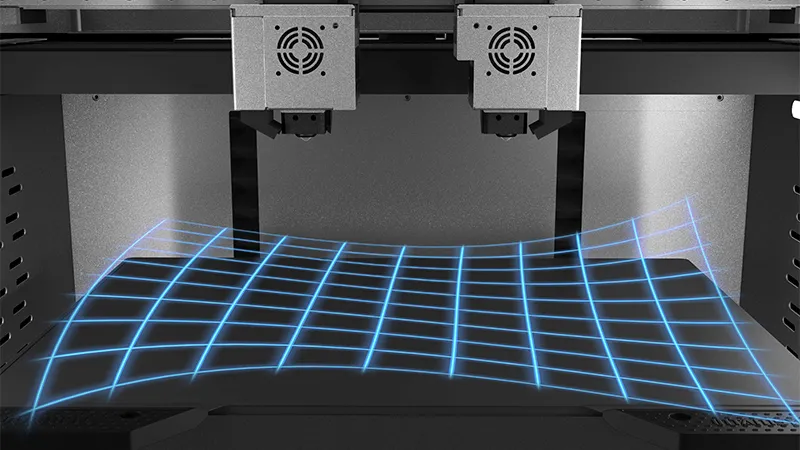

| Leveling: | Mesh Leveling (Max. 100 Points) |

| Materials: | PEEK, PEEK-CF, PEEK-GF, PEKK, PPS, PC, PC-ABS, PA6/66, PA6-CF, PA12, PA12-CF, ABS, ASA, HIPS, SP3030, etc. |

| Build Plate Temperature: | Max. 160℃ |

| Chamber Temperature: | Max. 100℃ |

| Functions: | Filament Runout Warning, Remote Control, Remote Printing, Online Update, Printing Recovery from Power Loss |

Machine

| Voltage: | 100~120 V/15 A or 200~240 V/7 A. 50/60 Hz |

| Max. Power: | 1500 W |

| Connectivity: | WiFi, Ethernet, USB |

| Screen: | 7-inch Touch Screen |

| Build Plate: | Magnetic Flexible Buildplate |

| Build Chamber: | Fully Enclosed Printing Chamber |

| Motor System: | High Performance Standalone Drive |

| Cooling: | Fan |

| Nozzle Maintenance: | Quick Release Design, Easy Installation and Disassembly |

| Filament Box: | Overall sealed box, Built-in Reusable Molecular Sieve to Keep Dry, Temp. and Humidity Real-time Monitoring, Standalone |

| Number of Spools: | 2 (Max. 1 kg/pc) |

| Resolution: | XY: 16 μm; Z: 1.25 μm |

| Filtering System: | HEPA + Activated Carbon, Replaceable |

| Printer Size: | 700 × 655 × 700 mm |

Safety

| Safety Design: | Safety Door Lock, Over Temperature Protection, Overload Protection, Warning Labels |

Slicing

| Slicing Software: | INTAMSUITE NEO |

| Supported File Types: | .stl/.3mf/.obj/.x3d/.g/oltp/.stp/.step/.iges |

| Operating System: | Windows |

Operating Environmen

| Working Temperature: | 0~30℃ |

| Working Humidity: | 20~70 % |

| Storage Temperature: | -20~55℃ |

| Storage Humidity: | 10~90% |