FUNMAT PRO 410

Filament 3D Printing Platform

High Performance and Fiber Composite 3D Printer

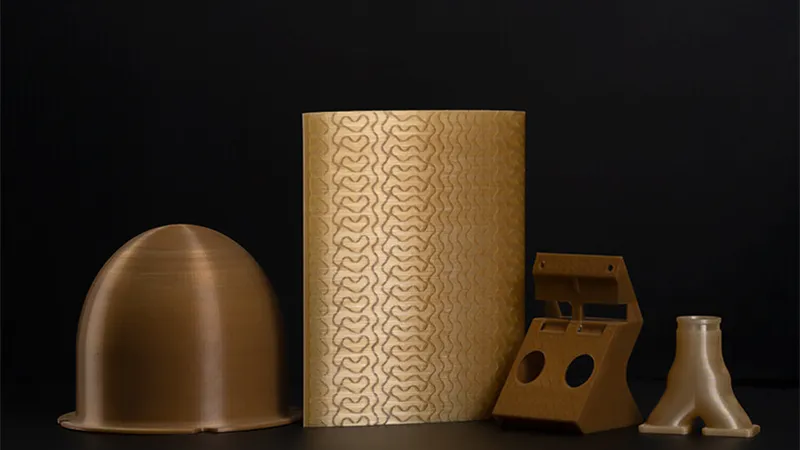

The FUNMAT PRO 410 is an industrial-grade FFF (Fused Filament Fabrication) 3D printer system characterized by its high-performance capabilities. Combining a respectable build volume with excellent print quality, the system is a great choice for professional and industrial users looking to 3D print high-performance parts with engineering materials.

Features

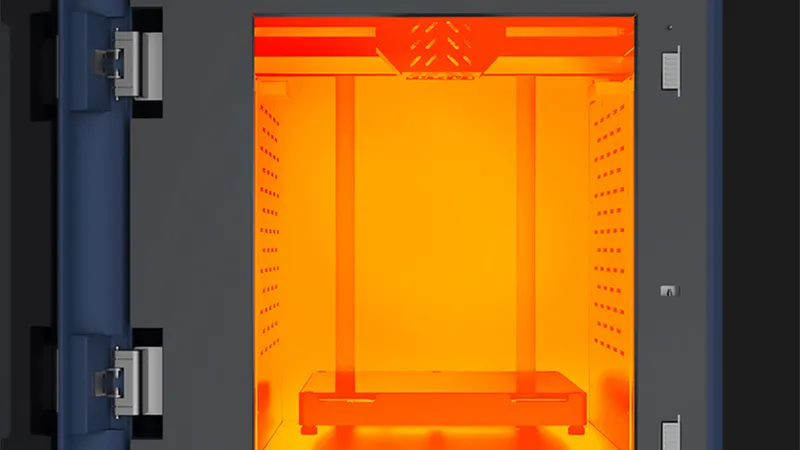

ADVANCED THERMAL DESIGN

Equipped with high-temperature, high-power dual-nozzle printing heads capable of reaching up to 500 °C, a maximum printing chamber temperature of 90 °C, and a maximum printing bed temperature of 160 °C , the uniformly heated chamber ensures better mechanical properties.

COST EFFECTIVE

Multi material and open-sourced filaments. High Performance: PEEK, PEEK-CF, PEEK-GF, PEKK, PAEK (AM200), PPS. Fiber Composite: Carbon Fiber-filled, Glass Fiber-filled. Engineering: PC, ABS, PC-ABS, ASA.

SMART DESIGN

Dual nozzle, automatic leveling, automatic feeding, jam warming and remote monitoring. Up to 30 days of continuous high quality printing.

Technical Data

Printing

| Technology: | FFF (Fused Filament Fabrication) |

| Build Volume (L × W × H) : | 305 × 305 × 406 mm |

| Layer Thickness: | 0.1-0.5 mm |

| Number of Nozzles: | 2 |

| Nozzle Temperature: | Max. 500℃ |

| Filament Diameter: | 1.75 mm |

| Printing Speed: | Max. 120 mm/s |

| Nozzle Diameter: | Default: 0.4 mm (Optional 0.25/0.6 mm) |

| Leveling: | Auto Leveling, Manual Leveling |

| Materials: | PEEK, PEEK-CF, PEEK-GF, PEKK, PPS, PC, PC-ABS, PA6/66, PA6-CF, PA12, PA12-CF, ABS, ASA, HIPS, SP3030, etc. |

| Build Plate Temperature: | Max. 160℃ |

| Chamber Temperature: | Max. 90℃ |

| Functions: | Auto-cleaning Nozzles, Filament Jam Warning, Filament Absence Warning, Remote Monitoring, Remote Printing, Printing Recovery from Power Loss |

Machine

| Voltage: | 200~240 V, 15A, 50/60 Hz |

| Max. Power: | 3000 W |

| Connectivity: | WiFi, Ethernet, USB |

| Screen: | 7-inch Touch Screen |

| Build Plate: | Ceramics Glass Plate with Magnetic Fixations |

| Build Chamber: | Fully Enclosed Printing Chamber |

| Motor System: | High-precision Closed-loop Drive |

| Cooling: | Liquid Cooling System & Fan |

| Filament Chamber: | Overall Sealed Design, Built-in Reusable Molecular Sieve to Keep Dry, Temp. and Humidity Real-time Monitoring, Auto Filament Feeding |

| Number of Spools: | 2 (Max. 3 kg/pc) |

| Travel Speed: | Max. XY 200 mm/s, Max. Z 50 mm/s |

| Resolution: | XY: 15.6 μm; Z: 1.56 μm |

| Filtering System: | HEPA + Activated Carbon, Replaceable |

| Printer Size: | 728 × 684 × 1480 mm |

| Printer Weight: | 230 kg |

Safety

| Safety Design: | Safety Door Lock, Over Temperature Protection, Overload Protection, Leakage Protection, Warning Labels |

| Safety Standards: | EN60204 |

| Certification: | CE, FCC, SGS |

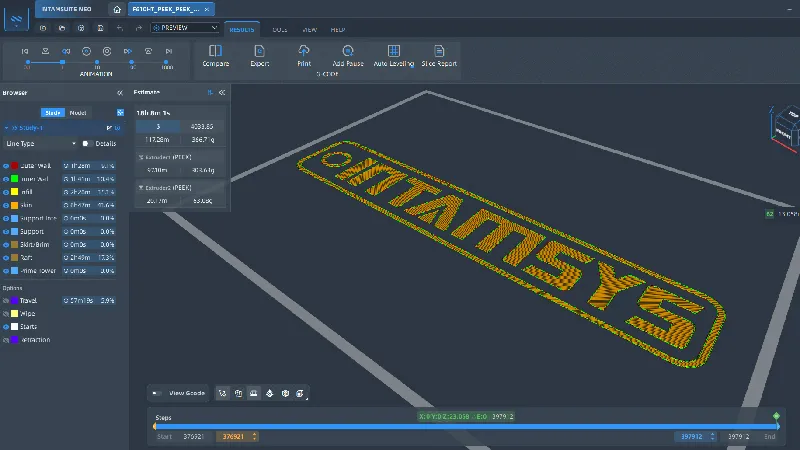

Slicing

| Slicing Software: | INTAMSUITE NEO |

| Supported File Types: | .stl/.3mf/.obj/.x3d/.g/oltp/.stp/.step/.iges |

| Operating System: | Windows |

Operating Environment

| Working Temperature: | 15~30℃ |

| Working Humidity: | 30~70 % |

| Storage Temperature: | 0~35℃ |

| Storage Humidity: | 20~90% |