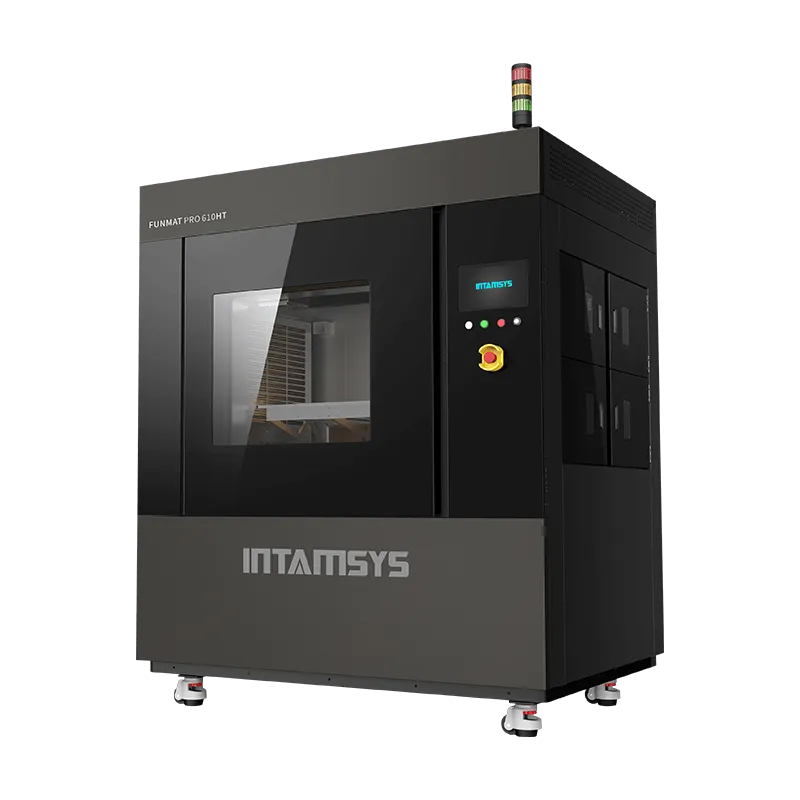

FUNMAT PRO 610HT

Filament 3D Printing Platform

Large Scale Industrial Production Grade

with High Chamber Temperature

Equipped to effectively handle the tough requirements needed to print with high-performance thermoplastics, this machine unlocks industrial-grade, high-quality additive manufacturing capabilities. The FUNMAT PRO 610HT is capable of handling almost every high-performance thermoplastic material available on the market. It comes with a dual extruder that can reach 500 °C and a heated chamber of 300 °C for premium repeatability with your part designs. This is our biggest FDM printer yet, this is a larger solution, boasting a build volume of 610 x 508 x 508 mm.

Features

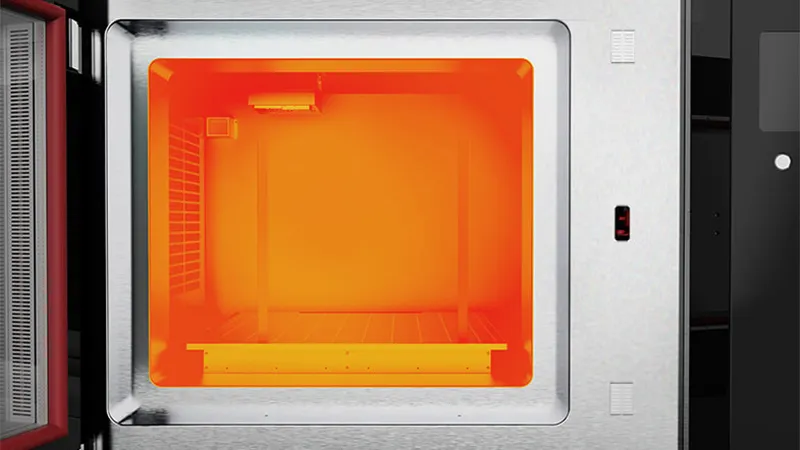

ADVANCED THERMAL DESIGN

Equipped with a uniformly heated chamber that can reach up to 300 °C and a dual extruder capable of reaching 500 °C, the FUNMAT PRO 610HT can print nearly all high-performance thermoplastic materials available on the market, ensuring superior print quality and enhanced mechanical properties of the printed parts.

HIGH EFFICIENCY

Print larger and print more. It offers higher strength, simplified post-processing, and is both time-saving and cost-effective. Bolster productivity by printing multiple parts simultaneously, ensuring uniformity of material properties across all printed parts.

GREAT PRINT QUALITY

With a closed-loop servo control system and a high-precision ball screw drive system, the accuracy of movement positions is significantly enhanced (with XY axis precision at 12.5 µm and Z axis precision at 1.25 µm), ensuring remarkable surface finish at high printing speeds.

Dual nozzles with support material solutions provide high-quality surface finishes on complex geometries.

Technical Data

Printing

| Technology: | FFF (Fused Filament Fabrication) |

| Build Volume (L × W × H) : | 610 × 508 × 508 mm |

| Layer Thickness: | 0.1-0.5 mm |

| Number of Nozzles: | 2 |

| Nozzle Temperature: | Max. 500℃ |

| Filament Diameter: | 1.75 mm |

| Printing Speed: | Max. 160 mm/s |

| Nozzle Diameter: Default: | 0.4 mm (Optional 0.6/0.8 mm) |

| Leveling: | Auto Leveling |

| Materials: | PEI 9085, PEI 1010, PEEK, PEEK-CF, PEEK-GF, PEKK, PPSU, PPS, PC, PC-ABS, PPA-CF, PPA-GF, PA6/66, PA6-CF, PA12, PA12-CF, ABS+, ABS, ASA, etc. |

| Chamber Temperature: | Max. 300℃ |

| Filament Chamber Temperature: | Max. 50℃ |

| Functions: | Auto-cleaning Nozzles, Filament Auto-reloading, Filament Jam Warning, Filament Absence Warning, Remote Control, Remote Printing |

Machine

| Voltage: | 3P 380 V 30 A/phase, 50~60 Hz or 3P 200 V 50 A/phase, 50~60 Hz |

| Max. Power: | 15 kW |

| Connectivity: | WiFi, Ethernet, USB |

| Screen: | 10-inch Touch Screen |

| Build Plate: | Flexible Buildplates with Vacuum Adsorption System |

| Build Chamber: | Fully Enclosed Printing Chamber |

| Motor System: | Servo Control System with High Precision Ball Screw |

| Cooling: | Liquid Cooling System & Fan |

| Filament Chamber: | Independent Sealed Chambers, with Active Heating and Dry Compressed Air (External Air Compressor Is Required), Keep Filament Dry During Printing, Auto Filament Feeding |

| Number of Spools: | 4 (Max. 3 kg/pc) |

| Travel Speed: | Max. XY 400 mm/s, Max. Z 50 mm/s |

| Resolution: | XY: 12.5 μm; Z: 1.25 μm |

| Printer Size: | 1710 × 1425 × 2350 mm (Incl. Warning lights) |

| Printer Weight: | 1450 kg |

Safety

| Safety Design: | Independent Safety PLC, Electromagnetic Safety Door Lock, Over-temperature Protection, Overload Protection, Emergency Stop Button, Double-layer Thickened Heat insulated Front Door, Heat-resistant Shield, Three-color Warning Light. |

| Safety Standards: | EN60204 |

| Certification: | CE, FCC, SGS |

Slicing

| Slicing Software: | INTAMSUITE NEO |

| Supported File Types: | .stl/.3mf/.obj/.x3d/.g/oltp/.stp/.step/.iges |

| Operating System: | Windows |

Operating Environment

| Working Temperature: | 15~30℃ |

| Working Humidity: | 30~70 % |

| Storage Temperature: | -10~54℃ |

| Storage Humidity: | 10~85% |