PRO 1500

Metal 3D Printing Post Processing

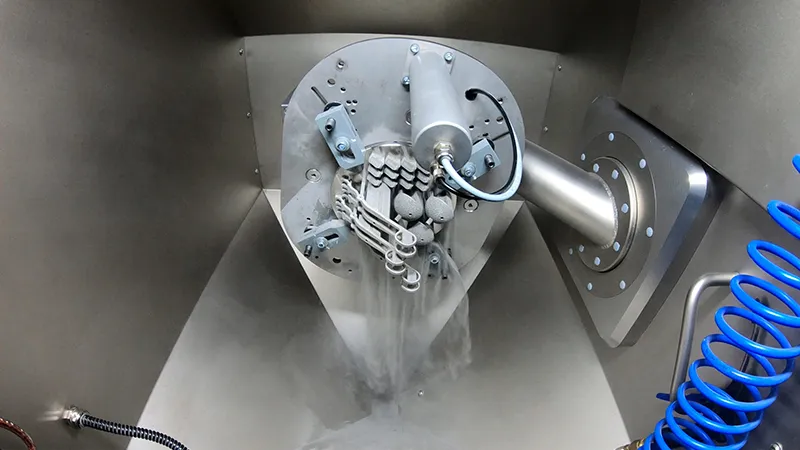

Efficient Powder Removal

for Additive Manufacturing

Efficient post processing of metal laser melted parts with our new depowdering technology.

At POWOO, we provide state-of-the-art depowdering solutions designed to meet the rigorous demands of additive manufacturing. Our systems are engineered for efficiency, safety, and precision, ensuring optimal performance for the most complex 3D printed structures.

The Problem We Solve

As 3D printing technology advances, the complexity of printed parts is increasing. This complexity requires sophisticated depowdering solutions that can efficiently and effectively remove powder from intricate geometries. Additionally, the need for efficient material removal and recycling is crucial for maintaining cost-effectiveness and quality in additive manufacturing. Our solutions are designed to meet these demands.

Features

MANUAL & AUTOMATED

Our solutions cater to various needs, offering both automated and manual systems for thorough depowdering.

CUSTOMIZABLE ROTARY TABLE

The rotary table is adaptable to different part sizes and shapes, ensuring comprehensive powder removal of build volume as requested.

INERT GAS INFUSION

Enhance safety and efficiency with our inert gas infusion technology, perfect for reactive materials like titanium and aluminum.

Technical Data

| External Dimensions (L × W × H): | 5700 × 5700 × 3200 mm |

| Workpiece Size (L × W × H): | 1500 × 1500 × 1700 mm (Incl. build plate) |

| Loading Weight: | Max. 4000 kg (Incl. build plate) |

| Net Weight: Approx. | 15000 kg |

| Inert Gas Protection: | Optional (Argon/ Nitrogen) |

| Doors: | Pneumatic top lifting doors |

| Explosion Proof: | Yes |

| Rotation: | 2-axis 360° |

| Operating System: | Independently developed operating system |

| Power Supply: | 380 V±10%, 3~/ N/ PE, 50 Hz |

| Rated Power | 15.75 kW |