Machine

SLM (Selective Laser Melting)

SLM (selective laser melting), officially called M-LPBF (metal laser powder bed fusion), is one of the most exciting 3D printing technologies available today. Powoo offers high quality, industrial level SLM systems featuring a wide range of build envelope size and production capability with great ROI. Equipped with powerful multi-laser options, advanced scanning systems, in-build monitoring and many other features, our metal machines produce high-quality, repeatable parts with excellent mechanical performance, accuracy, and surface finishes.

SLS (Selective Laser Sintering)

We provide world-class industrial-grade plastic Laser Powder Bed Fusion solutions including systems, materials and software for your direct additive manufacturing needs. With systems featuring open parameter sets and capable of achieving processing chamber temperatures between 190 °C ~ 340 °C Powoo offers a greater range of flexibility and freedom for machine operation and material selection.

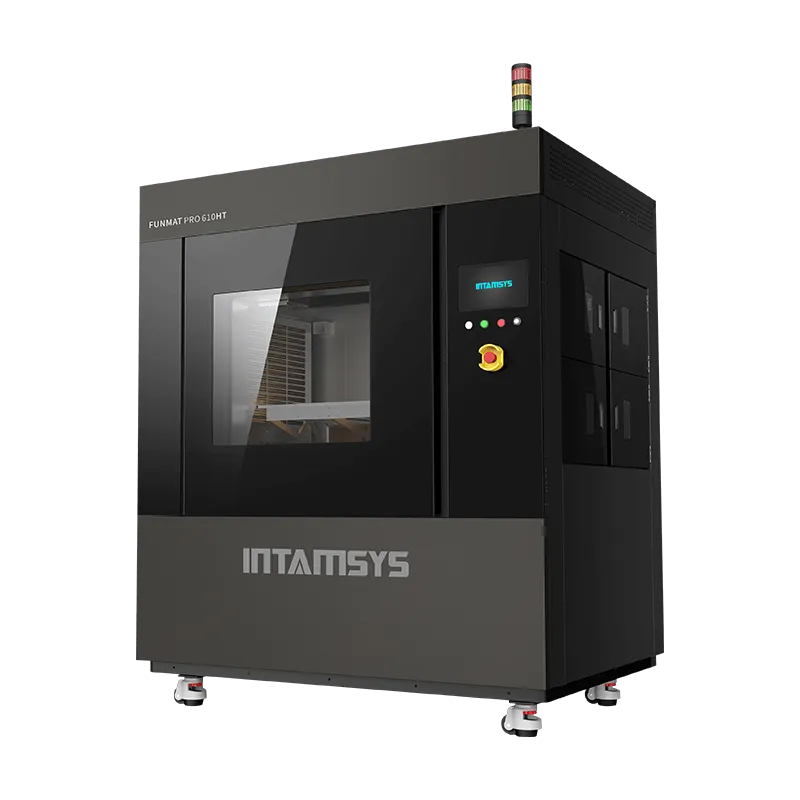

FDM

Fused Deposition Modeling is the most widely used additive manufacturing technique known for its extensive material selection, print accuracy, repeatability, and durability.

Our dedication lies in harnessing industrial FDM technology to accelerate the integration of 3D printing into end-use part production. We are actively transforming the limitations of traditional manufacturing, reinventing a more efficient and cost-effective manufacturing landscape.

Wire Cut

Wire EDM is a widespread technology in Additive Manufacturing post processing because it allows the detachment of the component from the 3D printing platform in a flexible and safe way. It can also operate on small parts or any other component producing waste, leaving the profiles flawless. This process has complete processing autonomy and reduces production costs.

We have developed a range of Wire EDM machines for your 3D printing post processing.

Depowdering

At POWOO, we provide state-of-the-art depowdering solutions designed to meet the rigorous demands of additive manufacturing. Our systems are engineered for efficiency, safety, and precision, ensuring optimal performance for the most complex 3D printed structures.

Our automated depowdering machines are designed to meet your industrial demands.